Drying Bamboo stalksFresh green colored bamboo stalks contain a lot of water and are therefore soft and relatively weak. Therefore, following the harvest of bamboo stalks, they must be dried for at least one year to make fishing rods. Professional ‘Wazao’ craftsmen typically dry them for more than 3 years. Drying Guidelines:For best results, first expose the green bamboo stalks outdoors in the sunlight until they turn to a yellow-straw color. This roughly takes 2 or 3 months. No matter if the weather is fine or rainy, drying should be completed by Spring to prevent Spring-time mold and/or insects, which means harvesting your bamboo stalks between autumn and winter. Drying should be done outdoors in the sunlight, followed by indoor storage in a dry place. Stalks

drying outdoors in the sunlight

Stalks being stored and dried indoors  Determining the rod actionThe action of a Marutake fly rod is determined by the

combination of bamboo stalks. Bamboo stalks have a hollow structure and

powerful fibers that accumulate on the surface. As a result, the

bamboo surface cannot be trimmed or sheared in order to change the

action of the rod. We therefore have to choose the best

combination of bamboo stalks from a large collection in order to create

our desired rod action. Stalk selection is much like a puzzle and, in

my opinion, is the trickiest part of the “Marutake” rod crafting

process. Heat treatment and straighteningBamboo stalks have a unique characteristic that allows them to harden through heat treatment, but remain soft and easy to bend while heated. Straightening Guidelines:

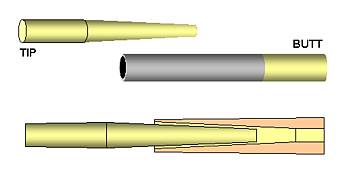

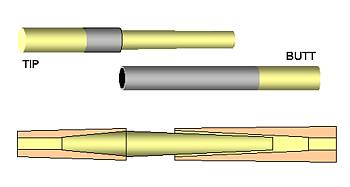

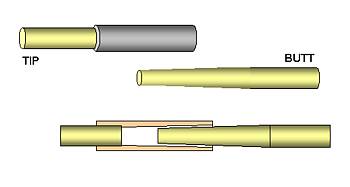

Western split cane rod makers, for example, use an oven to harden the bamboo strips. This is the best way to control heating temperature, but is not best suited for "Marutake" rod making. If you use an oven, the bamboo stalks will maintain the original bends before being straightened in the oven. "Tameki"We straighten the bamboo stalks using a tool called a "Tameki" which is made of hard wood. This is a very effective tool that is also simple and easy to make.  Making ferrules“Marutake” fly rods are usually made of 2 or more pieces of bamboo stalks, and connected with ferrules. We choose the best type of ferrule based on rod taper designs or the characteristics of the bamboo stalks. Butt over tip ferruleThis is the most popular ferrule used for “Marutake” fly rods. The tapered male ferrule tip section slips into the female (butt) section. It is light, strong and easy to make. Fly rod taper designs are generally composed of slow tapered butt sections and quick tapered tip sections. “Marutake” rods are the same, but it is hard to find quick taper bamboo stalks for tip sections. If you adopt this ferrule, the tip section diameter should be about 1mm smaller than the butt section. It also has the same tapering effect. This ferrule is useful with 2-piece fly rods or multi-piece fly rod tip sections.  Spigot ferruleWe choose this ferrule to join bamboo stalks with equal diameters, such as multi-piece rods. Internal male ferrule material must be hard, and traditional “Wazao” craftsmen make it from hard “Koyachiku” bamboo stalk. Graphite or fiberglass rods also use the same ferrule where spigot male ferrule is glued into the butt section to create smooth rod action, but “Marutake” rod internal male ferrule should be attached into the tip section to make a thicker, stronger female ferrule.  Sleeve ferruleThis ferrule joint bamboo stalk uses over-lapping sleeve material, and is a strong and versatile ferrule for “Marutake” fly rods. However, traditional “Wazao” craftmen have not adopted this ferrule because of its bulky shape. “Wazao” is made from pieces of bamboo stalks and the small diameter tip section is usually put into the large diameter butt section for easy carrying. If the rod section has a bulky sleeve ferrule, it is hard to put into the larger rod section. With fly rods, it is impossible to do even if it has a slim ferrule because of attached bulky guides. So bulky or slim ferrule is no matter. It is possible to choose various types of sleeve materials. For example, bamboo is a light and strong material and is easy to obtain for “Marutake” rod builders. Graphite carbon or fiberglass tubing are also good materials, but suited sizes are hard to obtain. Metal tubing is the strongest material, but is heavier than others.  |

Pass the bamboo

stalk through a low temperature flame until

the color darkens (bamboo stalks with small diameters will take less

heating time than thicker stalks). Once the stalk has been heated

and has darkened in color, remove from heat and straighten. After

this process, the original bend typically returns. Therefore it

is necessary to store the bamboo stalk in a humid place, such as the

bathroom, for a few days after heat treatment, and then repeat the heat

treatment process again. Repeat this process weekly until the stalk

becomes stable and permanently straight. Typically, it should be done 5

to 10 times.

Pass the bamboo

stalk through a low temperature flame until

the color darkens (bamboo stalks with small diameters will take less

heating time than thicker stalks). Once the stalk has been heated

and has darkened in color, remove from heat and straighten. After

this process, the original bend typically returns. Therefore it

is necessary to store the bamboo stalk in a humid place, such as the

bathroom, for a few days after heat treatment, and then repeat the heat

treatment process again. Repeat this process weekly until the stalk

becomes stable and permanently straight. Typically, it should be done 5

to 10 times.